This article introduces several forms of fuel injection for Isuzu EFI diesel engines

Isuzu G-IDSS Diagnostic Service System 03.2023 Download and Installation Service

EUI has been widely adopted by many major engine manufacturers, such as Detroi Diesel, Caterpillar,

John deere, Cummins, MTU and Volvo. At present, the fuel injection pressure of the unit injector to the

combustion chamber can reach 193.1~206.8MPa, and the solenoid valves of various electronically

controlled unit injectors are controlled by pulse electrical signals sent by the ECM (Electronic Control

Module). , the rate, timing, duration and end of the fuel injection are determined by the ECM. Many

engine manufacturers have adopted electronically controlled single-unit fuel injection pumps (EUP),

and major engine manufacturers using single-unit fuel injection pumps include Mercedes-Benz,

Volvo/Renault M/Mack, MTU/DDC and other companies. One-piece fuel injection pump is a separate

fuel injection pump for each cylinder of the engine. Each single-piece fuel injection pump is driven by

the camshaft of the engine, and only a short high-pressure oil pipe is used to deliver fuel to the cylinder

head of the engine. The fuel injector, the solenoid valve of each electronically controlled single fuel

injection pump is controlled by the pulse electric signal sent by the engine ECM, and the ECM

determines the fuel injection rate, duration and end time. At present, hundreds of engine manufacturers

around the world still use the basic fuel injection pumps and governors that Bosch has mass-produced

since 1927. Of course, the fuel injection pumps and injectors are now electronically controlled,

although many are still Still mechanically actuated by a camshaft and pushrod or overhead camshaft,

the fuel pressure is raised high enough to open the injectors or spring-loaded injection valves within the

injectors. The hydraulically driven electronically controlled unit injector (HEUI) jointly designed by

International and Caterpillar is widely used in their respective engine products. In HEUI, there is no

need for mechanical drive, and I is the high-pressure lubricating oil produced by the engine. to drive.

The four basic mechanical or electronically controlled fuel injection systems that have been used on

diesel engines are: spring-loaded or accumulator fuel injection systems; pulse injection pump fuel

injection systems derived from Bosch structures; distribution pump fuel injection systems. Constant

pressure or common rail fuel injection system. The electronic control distribution pump fuel injection

system detects the actual state of the engine based on the information of various sensors, and the

computer completes the following controls: first, fuel injection quantity control; second, fuel injection

time control; third, idle speed control. In addition, there are two additional control functions: one is the

fault diagnosis function; the other is the fault emergency function. The specific content of electronic

control is different according to different models. Some models can realize the above three controls of

fuel injection quantity, fuel injection time and idle speed, while some models only control the fuel

injection time. In terms of principle, the composition of the electronically controlled distribution pump

fuel system is almost the same as that of the in-line pump system except for the fuel injection pump.

The electric control distribution pump system can be divided into two types according to the control

method of fuel injection quantity and fuel injection time: one is position control type; the other is time

control type. The position-controlled electronically controlled distribution pump system is to replace the

ISUZU US-IDSS Diagnostic Service II Truck Diagnostic System 11.2022

mechanical governor in the VE distribution pump (mechanical distribution pump series) with an

electronically controlled actuator, which has been mass-produced by Bosch and Jackcell.

ISUZU IDSS Diagnostic Adapter System Support G-IDSS/US-IDSS/E-IDSS

The structure of the position-controlled electronically controlled distribution pump system is shown in Figure 1-1. The rotary solenoid actuator is adopted, and the position of the oil spill ring is controlled by changing the position of the eccentric ball at the lower end of the shaft due to the rotation of the rotor. The working principle is shown in Figure 1-2. ②Time-controlled electronically controlled distribution pump system (Figure 1-3) The microcomputer is equipped with a clock, through which the fuel injection end time is controlled, thereby controlling the fuel injection volume. The actuator that controls the end of fuel injection is a solenoid valve, which can control each fuel injection, so other fuel injection quantity control mechanisms can be cancelled. In addition, in the time control mode, the electronic circuit is relatively simple. Typical time-controlled dispensing pump products include: ECD-V3 dispensing pump of Denso Corporation of Japan, VP44 dispensing pump of Bosch Company of Germany, etc.

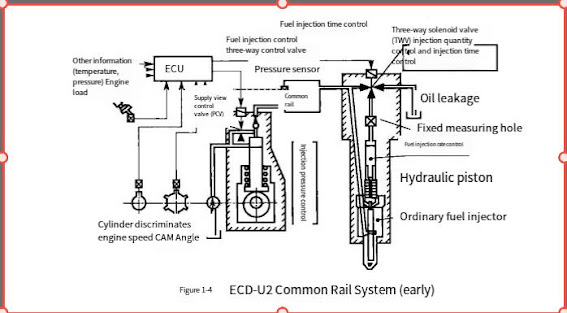

③ Electronically controlled high-pressure common rail fuel system In the 1990s, a brand-new fuel injection system——electronically controlled common rail fuel system was developed. Soon after it came out, it showed great advantages. The actual running state of the engine is detected by various sensors, and the fuel injection quantity, fuel injection time, fuel injection pressure and fuel injection rate can be optimally controlled through computer calculation and processing. The typical high-voltage electronically controlled common rail fuel systems are so far the most representative ones: the ECD-U2 system of Denso Corporation shown in Figure 1-4 and the UNIJET system shown in Figure 1-5.

11.2022 ISUZU E-IDSS Diagnostic Software Download and Installation Service