Description

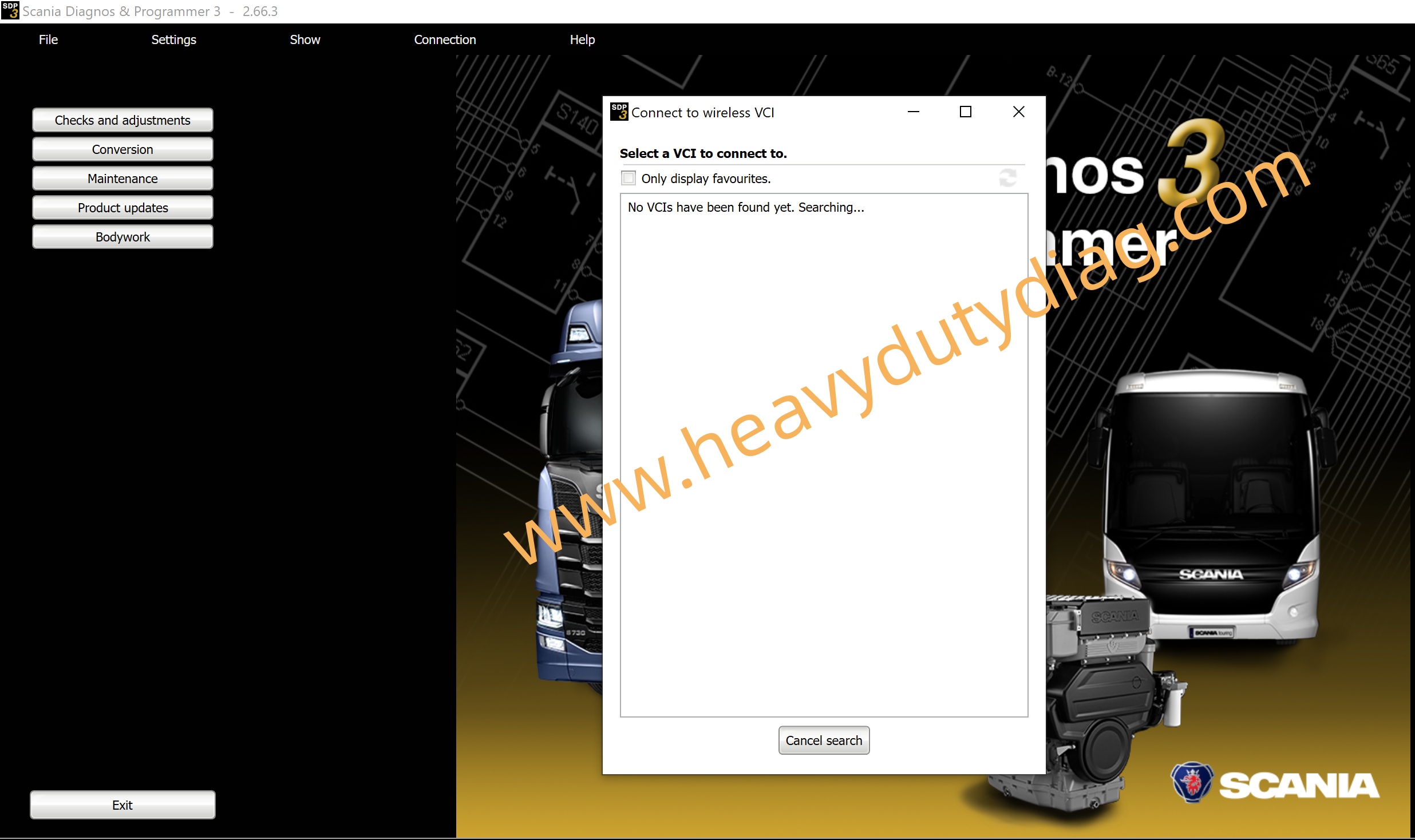

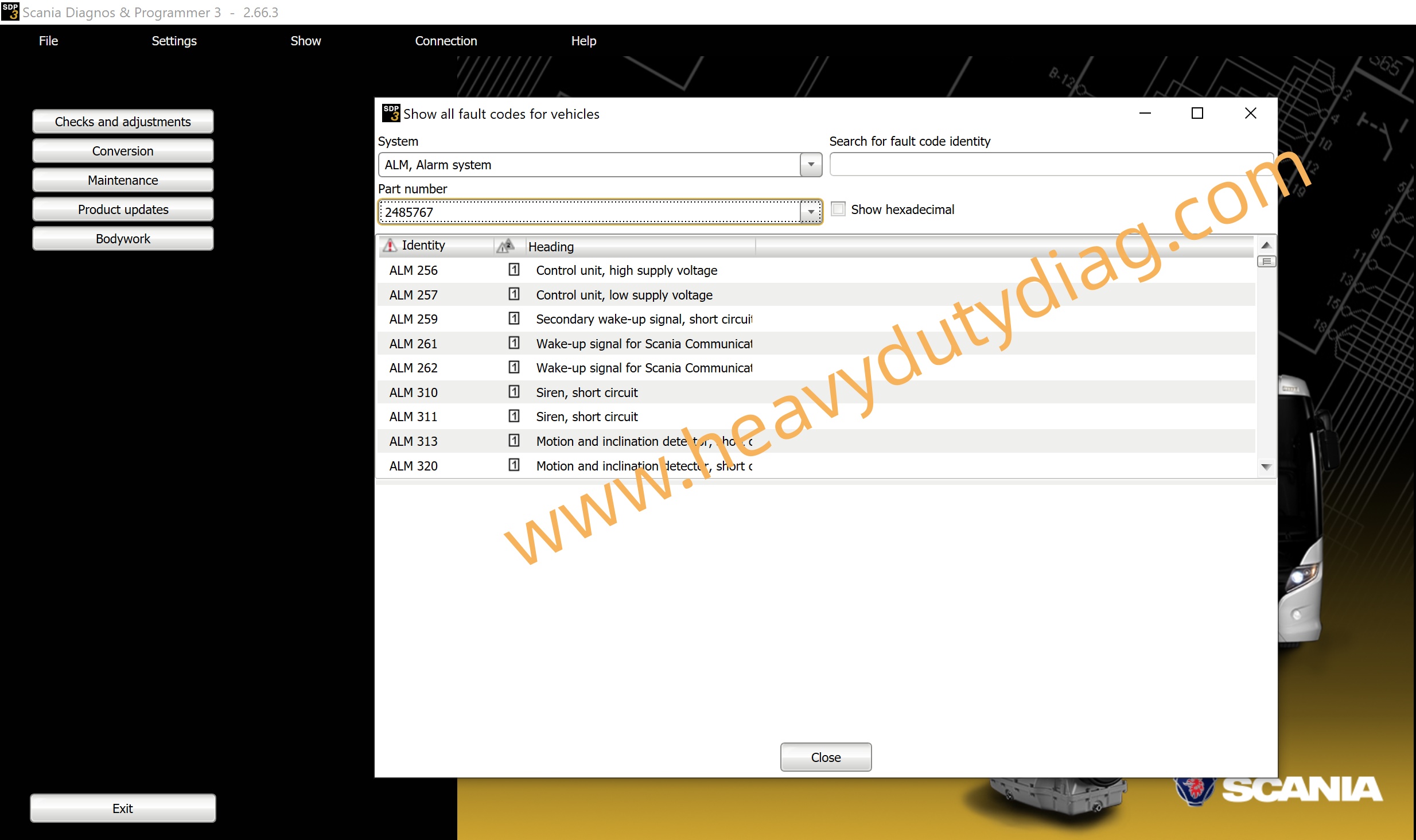

Scania SDP3 2.68.2 is the latest diagnostic software for Scania diagnostic tool VCI SDP3 (Scania Diagnosis & Programmer) software is an OEM software designed to maintain Scania trucks, other heavy vehicles and marine or industry engines over VCI diagnostic interface.

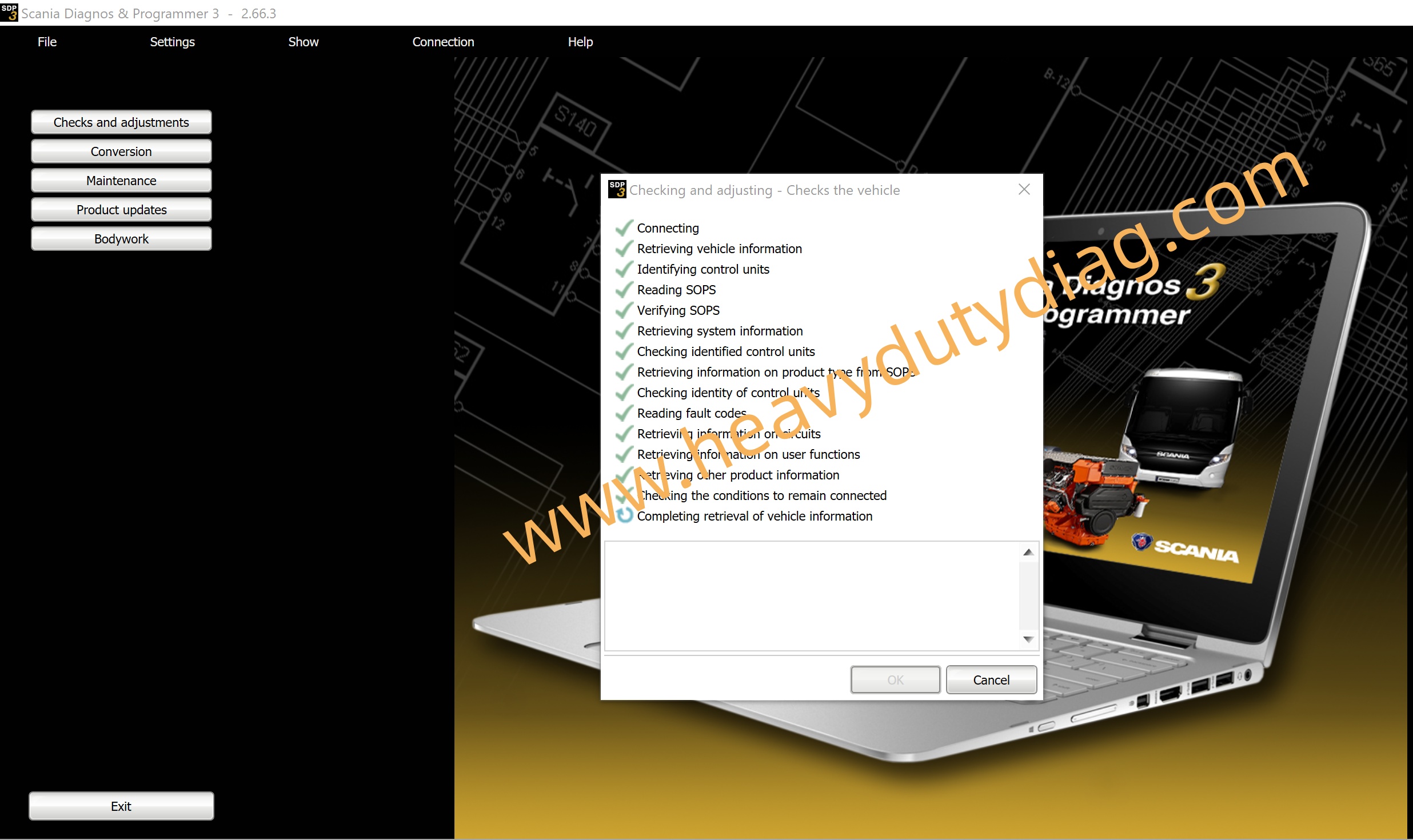

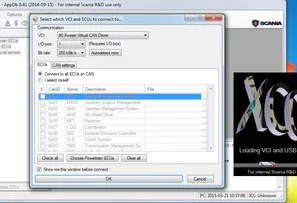

The SDP3 application includes fault code reading, assisted trouble shooting, parameter settings and more. SDP3 shall be installed on a PC/Windows platform, and connect to the vehicle through a vehicle communication interface (VCI).

Price only for One PC installation and Activation

Scania SDP3 Software Features:

Languages:German,English,Spanish,Finnish,French,Italian,Japanese,Korean,Dutch,Polish,Arabic,Portuguese,Russian,Swedish,Turkish,Chinese, Traditional Chinese,Romanian

OS:Window 7,Windows 8 and Window 10

Region:Worldwide

Version:2.68.1 Support Scania VCI3

Provide one free after-sale service

Need Netframework 4.8 or up version installed on system.(After installation,need restart your pc)

In order to install SDP3, administrator rights are required.

Scania SDP3 Functions:

Check and adjustments

Conversion

Maintenance

Campaign

Bodywork

Fault Codes

Fault Reporting

Programming of Control units

Supported resolving trouble codes to text description for the following types:

EMS (S6, S7, S8).

GMS (OPC4, OPC5).

RET (RET1, RET2).

AWD (AWD1).

EEC (SCR1, EEC3).

COO (COO6, COO7).

HMS (HMS1).

Some interesting options:

AdBlue ON/OFF.

EGR ON/OFF.

Chassis ID/VIN Change.

Immobilizer ON/OFF.

Truck Power INCREASE.

ECU Recovery.

ECU Reset.

ECU Unlock.

Scania SDP3 Support Systems:

EMS – Engine management system.

GMS – Gearbox management system.

RET – Retarder system.

AWD – All wheel drive system.

CLS – Clutch Control.

EEC – Exhaust Emission Control.

COO (COO7) – Coordinator.

BWS (BCI1) – Bodywork system.

Scania SDP3 Update Log New Features:

2.64.2

New general features

No major new general features in this version.

New system-specific features

New wizard Checking the climate system for MBS3.

The wizard has been developed specifically for checking the climate system in buses with Scania’s MBS3 electrical system for body.

The wizard is called Checking the climate system and can be found under Functions>Check>Comfort>Climate system.

General changes

No major general changes in this version.

System-specific changes

No major system-specific changes in this version.

Corrections

No major corrections in this version.

Exceptions

No major exceptions in this version.

2.64.1

New general features

Static high pressure pump performance testing for

engines fitted with EMS10.

A static high pressure pump performance test can now be carried out on engines fitted with EMS10 that have a fuel-lubricated high pressure pump.

The check is used to evaluate the individual performance of each valve in the high pressure pump.

Performance testing can be found under Checks > Powertrain > Engine > fuel system.

New system-specific features

No major new system-specific features in this version.

General changes

No major general changes in this version.

System-specific changes

No major system-specific changes in this version.

Corrections

No major corrections in this version.

Exceptions

No major exceptions in this version.

2.63.3

New general features

New function parameter for TMS3

The new function parameter for TMS3 allows retarder braking to be partly activated when ABS is activated.5

New function parameters for TMS4

A new function parameter has been developed for TMS4 for a maximum brake torque value at 10,000 kg axle weight.

A new function parameter has also been developed for TMS4 for a maximum brake torque value at 2,000 kg axle weight.

New system-specific features

No major new system-specific features in this version.

General changes

No major general changes in this version.

System-specific changes

Updating the calibration wizard for the electric

machine rotor position.

The Calibrating the rotor position on the electric machine wizard has been updated with information that the air pressure to the accessory circuit should be at least 7 bar.

Corrections

No major corrections in this version.

Exceptions

No major exceptions in this version.

2.63.2

New general features

No major new general features in this version.

New system-specific features

No major new system-specific features in this version.6

General changes

Updating injector codes for engines with EMS10 is no

longer necessary

It is no longer necessary to update injector codes for vehicles with engines equipped with EMS10.

Instead, the wizard “Calibrating injectors” for entering injector codes is replaced by an individual adaptation reset corresponding to the one used forengines without injector codes.

System-specific changes

No major system-specific changes in this version.

Corrections

No major corrections in this version.

Exceptions

No major exceptions in this version.

2.61.1

New general features

No major new general features in the issue.

New system-specific features

Exhaust gas aftertreatment for engines with the EMS

S8 or EMS EME1 control systems

The wizard Analysis of saved vehicle information in the event of high nitrogen oxide emissions, under Exhaust gas aftertreatment, is now activated for industrial and marine engines with the EMS S8 or EMS EME1 engine management systems.

For engines fitted with the EME1 engine management system, the Supplier’s software version must be 75.43.29 or later. This is a requirement for the engine control unit to be able to display saved signals for installations without an external clock signal.

The supplier’s software version can be found under the Description tab.

Two new wizards for AMS2

Two new wizards have been introduced, Troubleshooting using a manometer and Performance testing of the fluid part of the SCR system. The wizards apply to vehicles fitted with the AMS2 control system.

The wizards, together with a troubleshooting tree in Multi, simplify troubleshooting of the SCR system. The troubleshooting diagram will be introduced in WSM 03-95 and will be published on 2025-08-19.

Air pressure control for wastegate and exhaust brake on valve block V107

The function that previously controlled the degree of opening of the proportional valve on the valve block for the wastegate and exhaust brake is now replaced instead by an output pressure request.

It will continue to be possible to monitor the degree by which the proportional valves open.

The change covers the EMS10 control unit and can be found in the electrical system view under: EMS > E44 > EMS10 > solenoid valves > V107.

The action is taken to protect the wastegate and hoses from pressure loads higher than the maximum permitted 4.5 bar.

It will continue to be possible to load the exhaust brake at full system pressure, 8 bar.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.60.3

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.60.2

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.60.1

New general features

No major new general features in the issue.

New system-specific features

Checking the oil pressure with the engine switched off

The wizard makes it possible to check the oil pressure when the EMS10

DW6 engines are switched off.

The wizard is used to check whether it is possible to build up an oil pressure.

The check is carried out without starting the engine.

The wizard makes it possible to troubleshoot the oil system when, for

example, it is suspected that it will not possible to build up the required oil pressure.

Checking the battery state of health

Using the wizard, battery state of health is checked on the first generation of electric vehicles with BMU6. In order to use the wizard, the latest software version must be installed.

NOTE: At present, the vehicle must have a SOC window of at least 12-85%.

In future software versions, the test will work on all vehicles, BEV and hybrid, with BMU6 and 48 Ah battery regardless of SOC window.

The wizard shows on-board calculated battery state of health for each battery. The wizard can also be used to carry out a manual capacity check using an external charger. The test with an external charger takes 2-8 hours depending on how fast the charger is. The vehicle must also be discharged before the test.

There are no limitations on which charger can be used.

The purpose of the check is to provide a better picture of the residual capacity of the propulsion battery (battery state of health).

Both the software in BMU6 and SDP3 will be developed over time in order to ensure that the test is as accurate as possible. The test can deliver a result that is better than ±1%, provided the capacity is lower than 90%.

If the result is above 90%, uncertainty increases and the vehicle probably has more capacity than the result shows (+0-4%)

The value calculated on board is updated slowly over time and requires the correct conditions to be in place regarding temperatures, how the battery has been rested, the extent of the charging, etc. It is possible to force the test with an external charger and give the vehicle the correct conditions.

If the test is carried out, all battery modules will have a result. The wizard can also generate a PDF file with the test result and give the vehicle the correct conditions.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

2.59.3

New general features

No major new general features in the issue.

New system-specific features

APS2 product update

The product update applies to all vehicles fitted with APS2.

The current values for the condition of the desiccant container will be saved

before the APS2 product update is started. When the product update has

been carried out, all values are written back to the control unit. The values

for the condition of the desiccant container are not affected by the product

update.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.59.1

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

FLC3, improved method for dynamic calibration

The improved method for calibrating FLC3 means that the calibration time is now shorter.

The wizard can be found under Electrical system > FLC > FLC3.

After running the Calibrating the camera, dynamic calibration wizard, the vehicle only needs to be driven the entire distance of 50 km in exceptional cases.

The new method means that, while driving, you check that the value for

Dynamic calibration status changes from Not calibrated to Calibrated.

This signal is new and now included in the wizard Check the status of the camera calibration

When the value for Dynamic calibration status changes to Calibrated and the values for dynamic calibration are above 90%, calibration is complete and you can stop the vehicle. This usually occurs at a distance driven of 10-20 km. Depending on the circumstances, a distance driven up to 50 km may be required in exceptional cases.

If dynamic calibration has not been completed within a distance driven of 50 km, a fault code will be generated and you must redo the calibration.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.58.3

New general features

No major new general features in the issue.

New system-specific features

A wizard for checking oil pressure on DW6 engines,EMS10

The wizard has been developed to check the oil pressure in DW6 engines,EMS10.

The wizard can be found under:

Functions > Check > Powertrain > Engine > Basic engine.

The wizard makes it possible to carry out troubleshooting based on the oil pressure.

The wizard checks the oil pressure in relation to reference values to determine whether the pressure is within approved values. The wizard also allows you to choose between active or passive control of the oil pressure.

Diagnostic support for new BEV generation

New diagnostic tools have been developed for BEV generation 3.

A summary of the systems concerned and the wizards that have been developed for them is provided below.

The more comprehensive wizards that have been developed are then described.

BDM2

Control unit for the analysis and assessment of the electric power supply and electric power consumption. Manages the charge level and maintenance of 24 volt batteries.

Calibrating the electrical system

• Calibrating the battery data module during battery renewal

EMU1

Control system for cooling, charging and electric power take-off.

BMU7

Control system for cooling, charging and electric power take-off.

Electrical system wizard for checking the propulsion battery

• Classification of the propulsion battery

• Check risk factors

• Check insulation resistance

• Check battery state of health

• Check serial number

• Check temperatures

• Overview, temperature and voltage

• Check the cell voltages

• Check contactors

• Check flag for contactor fault

• Check pyro fuse flags

• Check flags for overvoltage

• Check flags for undervoltage

• Check flags for missing signals

• Check flags for overcurrent

• Check flags for high temperature

• View more information about battery components

• Battery module balancing support

TMS4

PTO control

• Overview of electric power take-off

Electricity supply, +24 V

• Battery health status

Under the function view for electric drive system performance

Electric drive system

• Overview of the VCB electrical system

• Overview of CAN network

• Initiation network overview

• Control of the electric power consumption of the VCB components

• Check insulation resistance

• Check propulsion batteries that are not responding

• Force closure of contactors in R126 and R130

Propulsion batteries

• Overview of voltage class B – Voltage levels and temperatures

• Overview of the components of the propulsion battery

• Classification of propulsion battery

• Checking contactors

• Propulsion battery serial number check

• Check battery state of health

• Check for flags due to abnormal voltage of temperature

• Check flags due to missing voltage and temperature signals

• Checking pyrofuses in propulsion batteries

• Support for module balancing

• Forced restart of BMU control unit

Charging the electric drive system

• Checking latch assembly for charging

• Checking signals for external charging

Electric drive system cooling system

• Checking the cooling system components

• Cooling system venting

Under the function view for powertrain and gearbox

Calibration

• Gearbox: Test for accelerometer adaptation

• Gearbox: Resetting the adaptations in the gearbox

• Electric drive system: Calibrating the rotor position on the electric

machine

Checks

• Gearbox, general: Checking CAN messages

• Gear control: Checking solenoid valves

• Gear control: Checking the gear changing function

• Gear control: Overview of the gearbox

• Gear control: Operate any coupling sleeve

• Shafts: Checking the rotational speed signals

• Oil system: Checking the gearbox oil level

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.58.2

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue

2.58.1

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

New calibration wizards for forward looking camera FLC3

NOTE:

The information applies to all vehicles fitted with FLC3 which have a forward looking camera with part number 3 004 425.

Due to a software error in cameras with part number 3 004 425, the regular workshop calibration with a target and measuring system is not working.

There are now 2 alternative methods for calibrating the camera, Dynamic calibration or Calibrating the camera in 2 steps, both of which replace the standard calibration method.

Select the calibration methods that best correspond to the conditions you have in order to carry out a calibration.

Dynamic calibration is carried out by first measuring the height from the ground up to the camera lens and then entering that measurement into the wizard. The value is then written to the camera.

After that, the vehicle must be driven a distance of at least 50 km on the road to complete the camera’s dynamic calibration.

Calibration of the camera in 2 steps is carried out as before using tools 2 200 024 (target) and 2 245 478 (measuring system) but with a changed height on the target and at two

different distances.

Since the target and measuring system are not adapted to the height or distances required for this method, modifications will be necessary. The height and distances required are described in the wizard.

The wizards are available from SDP3 2.57.2. In this issue, the Dynamic calibration wizard is only available with preliminary texts in English.

From issue SDP3 2.58.1 onwards, all texts have been translated.

The wizard for calibrating distance sensors in traffic Applies to vehicles fitted with DIS3.

The wizard for calibrating distance sensors in traffic has been updated from SDP3 2.57.2 onwards.

In earlier versions of SDP3, it was not possible to complete the calibration process. This has now been corrected.

The wizard for calibrating distance sensors in traffic can be found in the electrical system view -> DIS3 -> Calibration.

Exceptions

No major exceptions in the issue.

2.57.2

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

SDP3 now controls the engine speed when running the “Measuring braking force” wizard

The “Measuring braking force” wizard, which can be found under Auxiliary brake in check wizards for the powertrain, has been changed so that SDP3 now controls the engine speed during testing.

SDP3 now controls the engine speed when running the “Testing retarder performance” wizard

The “Test of retarder performance” wizard, which can be found under Auxiliary brake in check wizards for the powertrain, has been changed so that SDP3 now controls the engine speed during testing.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.57.1

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.56.3

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

2.56.2

New general features

No major new general features in the issue.

New system-specific features

No major new system-specific features in the issue.

General changes

No major general changes in the issue.8

System-specific changes

No major system-specific changes in the issue.

Corrections

No major corrections in the issue.

Exceptions

No major exceptions in the issue.

![[02.2025] ISUZU G-IDSS Global Truck Diagnostic Software Installation Service](https://www.heavydutydiag.com/wp-content/uploads/2022/05/1-24-297x223.jpg)