This article mainly introduces the Perkins 2806F engine flexible exhaust pipe installation procedure

Perkins EST Diagnostic Adapter- High Quality

1. Ensure that all components of the flexible exhaust pipe assembly are clean and free from wear and damage. If necessary, replace any components of the flexible exhaust pipe assembly that are worn or damaged. Refer to your Perkins distributor for further information.

2. If the flexible exhaust pipe assembly was

previously disassembled. Follow Step 2.a through Step 2.j to assemble the flexible exhaust pipe

assembly.

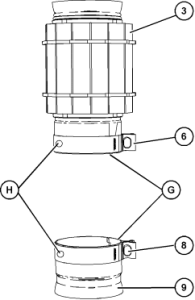

a. If original bellows are to be reinstalled, place the internal area in Position (G) of the bellows on a suitable support. Use a 3 mm (0.118 inch) to

drill a pilot hole through the spot weld in Position (H) on clamp (6).

Note: Do not center punch the spot weld on

clamp (7).

b. Use a 6.5 mm (0.256 inch) to drill out spot weld in Position (H) on clamp (6). Remove the clamp

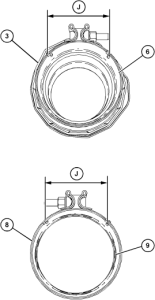

Position a new clamp (6) onto bellows (3). Hand tighten the clamp . Ensure that the center of the clamp is central to Slots (J) on the bellows. The clamp must be flush with the end of the bellows.

Note: Ensure that the bellows are not subjected to any undue stress.

g. If a new bellow (3) are installed, clamp (6) will be pre-installed to the bellows.

Note: Ensure that the bellows are not subjected to any undue stress.

h. Position a new clamp (8) onto adapter (9). Hand tighten the clamp . Ensure that the center of the clamp is central to Slots (J) on the adapter. The clamp must be flush with the end of the adapter.

i. If a new adapter (9) are installed, clamp (8) will be pre-installed to the adapter.

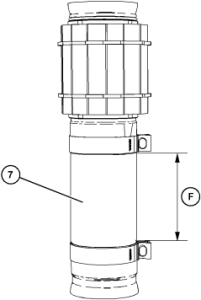

j. Install tube assembly (7), align the tube

assembly with the temporary marks on bellows (3) and adapter (9). Tighten clamp (6) and

clamp (8) hand tight.

2023A& 2022A Perkins EST Electronic Service Tool Diagnostic Software Full Provide Installation Service

NOTICE

Inspect the bellows for damage prior to installation. If there is any damage to the convolutions, discard the bellows. If there is any difficulty in installation after the repair, discard the bellows.

1. Check the flexible exhaust pipe assembly for damage. Refer to your Perkins distributor for further information.

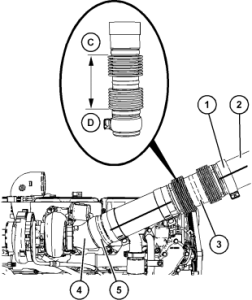

2. Install a new ball clamp (1) and a new ball clamp (5). Ensure that the ball clamps are correctly

orientated.

NOTICE

3 Failure to reinstall the bellows into the original posi- tion will result in a failure of the bellows and possible emissions failure.

Note: Ensure that the assembly of the flexible exhaust pipe is supported at all times.

4. Ensure that ball clamp (1) and ball clamp (5) are correctly seated onto the assembly of the flexible exhaust pipe. Hand tighten the ball clamps.

5. Tighten ball clamp (1) and ball clamp (5) to a torque of 35 N·m (26 lbft).

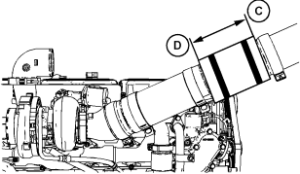

- Cutcablestraps from the suitable material that

was encasing the bellows (3) between Position (C) and Position (D). Remove the suitable material

from the bellows.