This article introduces the disassembly of Doosan DX340LC-5 excavator swing reduction gear

1. Park on firm and level ground.

2. Lower front attachment (bucket) to ground.

3. Shut down engine.

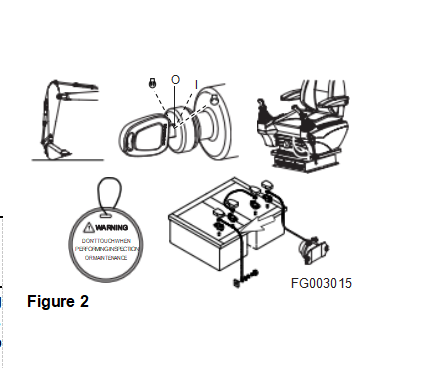

4. Set safety lever on “RELEASED” position.

Doosan Diagnostic Tool UVIM Support Doosan Excavators High Quality

5. Turn starter switch to “I” (ON) position.

WARNING!

If engine must be running while performing maintenance, always use extreme caution. Always have one person in cab at all times. Never leave cab with engine running.

6. Fully stroke work levers (joysticks) in all directions to

relieve any pressure from accumulators.

7. Set safety lever on “LOCK” position.

8. Turn key to “O” (OFF) position and remove from starter

switch.

9. Hang a maintenance warning tag on controls.

10. Disconnect negative (-) battery cable leading to frame from

battery.

2023.07 Doosan DMS-5 Data Monitoring System Diagnostic Software

11. Tag and disconnect hoses from swing motor (1, Figure 3).

Plug and cap hoses and ports to prevent contamination

from entering hydraulic system or component.

12. Disconnect tube (2) from drain cock (3) and hose fitting (7)

from fill hole.

13. Remove twelve bolts and washers (4, Figure 3) holding

swing reduction gearbox (5) to frame.

14. Using a suitable lifting device, slingswing motor (1, Figure

3) and remove swing motor and reduction gearbox (5) as

an assembly from unit.

NOTE: A drain cock (3, Figure 3) and tube are on side

of gearbox. Be careful not to damage valve or

tube.

NOTE: There are two alignment pins (6, Figure 3), one

on each side of reduction gearbox